|

|

M.R.Trade Links Pvt ltd. |

|

|

|

|

|

DAUB MOULDERS

|

|

|

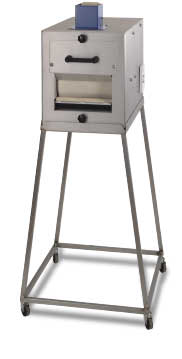

The MINI-MOULDER

for hotdogs and fingerrolls helps you save time and is ideal for

use in combination with a bun divider rounder. It is a reliable

machine, simple to operate with high capacity (up to 2.400

pieces per hour). Experience shows the rolls have a better

volume than those formed by hand.

The machine is covered in stainless steel; cleaning is simple

through the removable front plate. It can easily be put on a

table or on an available stainless steel stand with wheels.

|

| |

|

|

A roller

laminates the pre-rounded dough piece. Then it is rolled between

a drum, a felt belt and an adjustable pressure board. Model 200

has two rollers for pre-lamination. |

|

Specifications:

|

Model |

Product |

Weight range

gr |

Max. length

cm |

LxWxH

cm |

Weight

kg |

|

MM-100F |

Fingerroll |

30-100 |

15 |

71x31x45 |

30 |

|

MM-100H |

Hotdog |

30-100 |

15 |

71x31x45 |

30 |

|

MM-100C |

Fingerrol/hotdog |

30-100 |

15 |

71x31x45 |

30 |

|

MM-200 |

Small

loafs |

20-200 |

23 |

71x38x55 |

45 |

Weight range and lenght are dependent on dough consistency

Power: 0,25 kW

|

|

|

|

|

|

|

Shop

slicers are equipped with a bread pusher and are ideal for the

bakery store where bread is sliced and packaged at the

customerís request. They are manufactured both as table and as

standing models. Semi-automatic machines are activated by a

carrying handle, which the operator pushes backward. Automatic

machines have a motor driven pusher and slicing starts after

simply pressing the start button.

The available slice thicknesses are: 10,11,12,13,14,16,18 or

20 mm.

Specifications:

|

Model

|

Semi-automatic

|

Automatic

|

Table model

|

Stand model

|

Max. bread length cm

|

LxWxH

cm

|

Weight kg

|

Power kW

|

|

201/40

|

X

|

|

X

|

|

40

|

73x64x62

|

105

|

0,37

|

|

201/46

|

X

|

|

X

|

|

46

|

73x70x62

|

110

|

0,37

|

|

201/52

|

X

|

|

X

|

|

52

|

73x77x62

|

130

|

0,37

|

|

202/40

|

X

|

|

|

X

|

40

|

73x64x113

|

115

|

0,37

|

|

202/46

|

X

|

|

|

X

|

46

|

73x70x113

|

120

|

0,37

|

|

202/52

|

X

|

|

|

X

|

52

|

73x77x113

|

140

|

0,37

|

|

203/40

|

|

X

|

X

|

|

40

|

73x55x62

|

130

|

0,55

|

|

203/46

|

|

X

|

X

|

|

46

|

73x61x62

|

135

|

0,55

|

|

203/52

|

|

X

|

X

|

|

52

|

73x67x62

|

155

|

0,55

|

|

204/40

|

|

X

|

|

X

|

40

|

73x55x113

|

140

|

0,55

|

|

204/46

|

|

X

|

|

X

|

46

|

73x61x113

|

145

|

0,55

|

|

204/52

|

|

X

|

|

X

|

52

|

73x67x113

|

165

|

0,55

|

|

|

GRAVITY FEED SLICER

|

|

|

|

The

gravity feed slicer 205 is ideal for slicing bread in the

production area. It is equipped with an infeed board where the

bread is moved down by gravity. This machine is suitable for

sandwich loafs / toast bread and can slice up to 500 pieces

per hour continuously.

The available slice thicknesses are: 10,11,12,13,14,16,18 or

20 mm.

Specifications:

|

Model

|

Max. bread length cm

|

LxWxH

cm

|

Weight kg

|

|

205/40

|

40

|

97X55X191

|

180

|

|

205/52

|

52

|

97X67X191

|

205

|

Power 0,37 kW

|

|

SEMI INDUSTRIAL SLICER

|

|

|

|

|

The

semi-industrial breadslicer 208 is the right answer for

slicing all types of loafs in the production area. The double

infeed belts with electronic variable speed continuously feed

the bread to the cutting blades. It has a high hourly

production of up to 800 pieces per hour continuously.

The available slice thicknesses are: 10,11,12,13,14,16,18 or

20 mm.

Specifications:

|

Model

|

Max. bread length cm

|

LxWxH cm

|

Weight kg

|

|

208/40

|

40

|

194X55X136

|

215

|

|

208/52

|

52

|

194X67X136

|

235

|

Power:

1,0 kW

|

|

OPTIONS

|

|

|

A blowing device for

plastic bags can be attached to slicer, either on the left or

the right side. A ventilator blows open the first bag. The

operator pushes in the sliced bread and takes it away, after

which the blower automatically opens the next bag. All major

manufacturers supply the special bags for this system.

|

|

|

To suit local

regulations in all countries, special safety covers can be

supplied. |

|

Options |

| Blowing

device for plastic bags |

| Oil

lubrication of the knives |

| Stainless

steel frame for shop slicers |

| Two

different slice thicknesses left and right |

| Machine on

four wheels |

| Safety

guards front and rear |

| Stainless

steel knives |

| Teflon

coated knives |

|

Single phase

execution for shop slicers |

|

|

| |

|

|